Description

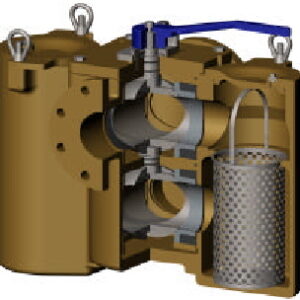

The type of valves used for Eaton model 950 duplex strainers are usually butterfly valves, although ball valves can be used if required. There are single, double and triple offset butterfly valves as well as 1, 2 and 3 piece ball valves; the valves used will depend upon the specific requirements of your application. It is possible to use a pair of 3 way diverting ball valves that are linked together to accomplish a similar diversion, however it is uncommon. It is also possible to install actuators to automate the sequence and eliminate manual manipulation of the valves.

The baskets for model 950 duplex strainers might require an overhead winch or lifting mechanism.

If your particle load is continuous and the pipeline 6″ or larger, consider an automatic strainer which might cost the same or slightly less and provides the advantage of automatic operation without interruption of process flow.

For some applications we can supply a hinged “quick-opening” basket chamber cover design, which is especially useful for larger size strainers that would otherwise require a cover lifting davit assembly.

Reviews

There are no reviews yet.