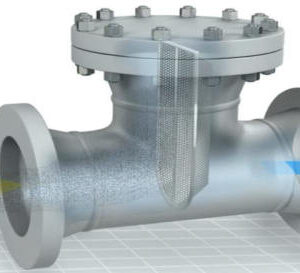

Tee Strainer

EATON MODEL 91 T STRAINERS

Custom Fabricated T Strainers

Tee strainers are a style of compact custom fabricated simplex strainer to satisfy requirements that a cast Y strainer cannot, such as being constructed with a corrosion allowance, having an ASME code stamp or made with an oversized body for a higher open area ratio. In addition to being a compact design, T strainers can be installed vertically if the flow path downwards, just like a Y strainer.

Options for Custom Fabricated T Strainers

CRN registration, ASME U code stamp, ASME UM stamp (where applicable), Welding procedures (WPS, PQR, WPQ), Internal/External coatings per customer’s specification, Non-destructive examination (L.P., X-ray, PMI, UT, MT, LD) and Corrosion Allowance.

Documention Available for Custom Fabricated T Strainers

NDE report, Seismic calculations, Wind load calculations, ASME code calculations, Certified material test report, Domestic export documentation.

When comparing the flow coefficient values of T strainers and basket strainers you’ll notice that they are very similar, meaning you can take advantage of the compact tee strainer size without sacrificing (making higher) your differential pressure. This is possible due to the special convoluted screen design of the Eaton model 91 T strainer which increases the total filtration area.

The greatest difference between T strainers and basket strainers is the volume of particulate which can be retained. The screen design and vessel size for T strainers is less than it is for a corresponding size basket strainer, which means that T strainers are better suited for applications having a low percentage of particulates (similar to Y strainers). This makes T strainers ideal as condensate and boiler feed pump suction strainers due to their low clean differential pressure and the expected low volume of particulate.

Showing the single result