Basket / Duplex Strainer

Duplex Style Strainers

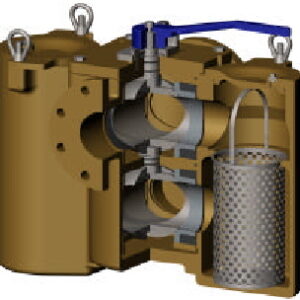

The duplex strainer design is for continuous duty applications which cannot tolerate an interruption in flow for basket cleaning; i.e. the system flow cannot be interrupted.

A duplex strainer is essentially two simplex strainers connected with a three-way valve used to divert flow from the dirty basket chamber to the clean basket chamber.

The style of valve used to divert the flow differs with cast and custom fabricated designs. Cast designs require only a lever to divert the flow because there’s one three-way valve being operated. The flow remains continuous because as one side of the valve closes, the other side opens.

The custom fabricated designs often use four butterfly valves; sometimes they can be linked to a single operator, however more often they need to be individually opened and closed, thus the order they are manipulated becomes important. You begin by opening the inlet valve to the clean chamber, followed by opening the outlet valve for the clean chamber, then closing the outlet valve for the dirty chamber and finally closing off the inlet valve to the dirty chamber.

Once the dirty chamber is isolated, the access and change-out procedure is the same as it is for a simplex strainer.

The choice of a cast or custom fabricated design is typically dictated by the design criteria for the application; castings are suggested wherever applicable to reduce cost and lead time.

Showing all 7 results

-

Cast 316SS Duplex Strainers

Read more -

Cast Bronze Duplex Strainers

Read more -

Cast Iron Duplex Basket Strainers

Read more -

Cast Steel Duplex Strainers

Read more -

Custom Fabricated Duplex Strainers Eaton model 950 duplexed basket strainers

Read more -

Diverting Cartridge Valve Duplex Strainers Eaton model 53BTX duplex basket strainers

Read more - Sale!

Eaton USA Duplex Basket strainer

AED 5,500.00 Add to cart