Gas/Liquid Separators

Wright-Austin Gas/Liquid Separators

Centrifugal separators remove droplets >10 microns with 99% efficiency

Call us at 00971 556099497 to speak with a sales engineer

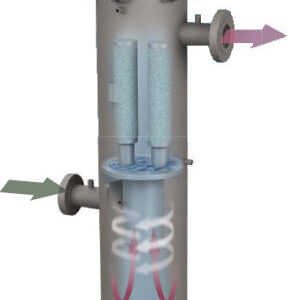

Type T air/liquid separator Wright-Austin™ established the industry standard for air/liquid separators over 125 years ago. Their product line includes both cast products (cast iron, cast steel and cast 316SS) as well as fabricated products, typically constructed from carbon steel, 304 SS or 316SS, although they can be constructed of most alloys available in pipe and plate form. Acquired by Hayward in 1996 and subsequently Eaton Hydraulics in 2005, our company has represented the Wright-Austin product line through our USA Principle since 2007.

What are gas/liquid separators?

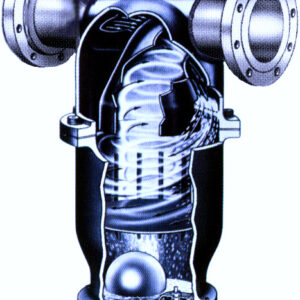

They are pressure vessels which create an internal vortex to remove entrained droplets and particles from a process gas, usually compressed air or steam, although there are many petrochemical applications involving other gasses. Having no moving or serviceable components and due to the patented internal geometry of the separator, droplets and particles coalesce and drain from the separator with minimal pressure drop.

The efficiencies for most of our separators are 99% for removal of droplets and entrained particulate > 10 microns in size, although we do offer versions which can remove finer droplets including a coalescing style for removal of droplets as fine as 4 microns and a two stage design for removal of droplets >0.30 microns with 99.7% efficiency.

Cast products are typically stocked in non-assembled form, requiring 3-5 work days for assembly and testing prior to shipment after receipt of an order. Fabricated separation products require 6-8 weeks for most “standard” (existing designs) and up to 12 weeks for custom designed separators.

Showing all 16 results

-

30L Style Horizontal Gas Liquid Separators

Read more -

Coalescer – Wright-Austin TF Gas Liquid Separators

Read more -

Coalescer Gas Liquid Separators

Read more -

Coalescer Gas Liquid Separators Fine mist separation (>5 microns) with 99% efficiency

Read more -

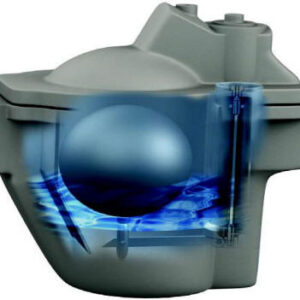

Condensate Drain Traps – Model 90-AC and 95-AC

Read more -

Drain Traps Model 230-AC

Read more -

Drain Traps Model 300 Series-AC Cast Iron Float Style Drain Traps

Read more -

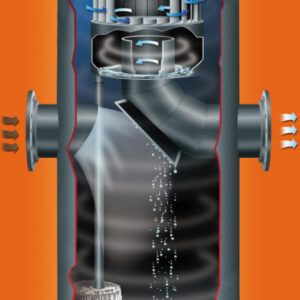

Gas Liquid Separators (Separation of high solid, sludgy gasses down to >10 microns)

Read more -

High Solid

Read more -

Horizontal – ST Wright-Austin Gas Liquid Separators Traps

Read more -

Horizontal – Wright-Austin R Gas Liquid Separators

Read more -

Horizontal – Wright-Austin TS Gas Liquid Separators

Read more -

Horizontal – Wright-Austin Type T Gas Liquid Separators

Read more -

Type 60-I and 70-I Separator Elements

Read more -

Vertical Gas Liquid Separators

Read more -

Wright-Austin Exhaust Heads

Read more