Description

Cast Iron exhaust heads

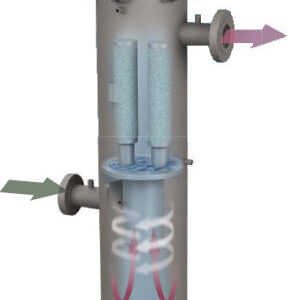

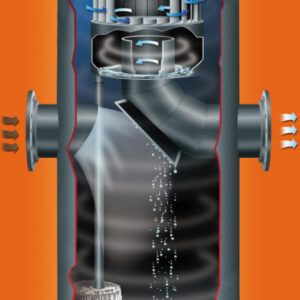

Wright-Austin cast iron exhaust heads are designed for long service life, the body, cover and separating element are constructed of high tensile cast iron which resists fractures and corrosion. Cast iron exhaust heads are designed to remove entrained droplets from steam vent lines, often located on rooftops. They remove droplets as fine as 10 microns with 99% efficiency, the droplets are sent to a common drain for reclamation or disposal. Exhaust heads reduce the visible steam exhaust plume, reduce the loss of boiler treatment chemicals and wetting-out or corrosion of nearby surfaces.

Although an exhaust head has a sound reducing, muffler-like effect, that is not its design purpose. Its purpose is strictly for removing entrained liquid from the vented steam, the indirect pathway reducing noise is a byproduct of its design. There are vent mufflers designed specifically for noise reduction, however it is not a product we offer.

ASME Code Stamps and CRN are not applicable because exhaust heads are not pressure vessels. The components to build cast iron exhaust heads are usually stocked items and shipments made within 1 week after receipt of an order. If the lead time is critical, please contact our office and obtain a lead-time estimate based upon the current manufacturing backlog.

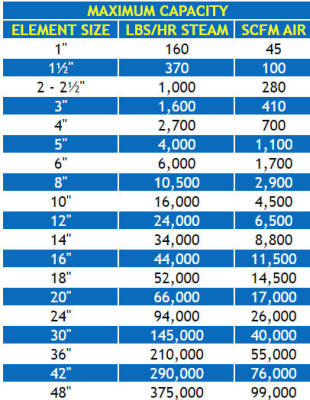

Wright-Austin Cast Iron Exhaust Head Drawings: (includes list of maximum capacity by size)

Fabricated Exhaust Heads

Wright-Austin custom fabricated exhaust heads are used to reduce visible condensate plumes and to recover various chemistries prior to venting to atmosphere. Fabricated exhaust heads remove entrained droplets as fine as 10 microns with 99% efficiency thereby reduce carry-out and contamination of nearby structures.

Carbon steel exhaust heads have a 304 stainless steel internal vortex vane. Carbon steel is used in lieu of cast iron when the operating temperature, compatibility or sizing exceeds the cast iron design. ASME Code Stamps and CRN are not applicable to exhaust heads because they are not pressure vessels. We can provide custom coatings and we can also fabricate from other alloys such as stainless steel. Usually the exhaust head is constructed of the same material as the pipe to which it is installed.

How to Size an Exhaust Head

When sizing an exhaust head, the pressure used to size it should always be Atmospheric (14.7 PSIA); an exhaust head is essentially a pipe fitting with one end fully opened to atmosphere (14.7 PSIA) and therefore its the flow rate that determines the exhaust head size. Fabricated exhaust heads enable customizations and NDE/NDT which are not applicable to cast iron exhaust heads. For example, we can attach a smaller size inlet nozzle to match your existing/design vent pipe size. We can also provide other connection types besides the standard 150# flanged design.

There is no need to shield the exit orifice of an exhaust head from rainwater because it will automatically be diverted to its drain. Sometimes customers specify the addition of a screen to prevent birds from nesting within the exhaust head, but this might only be a concern if there are extended periods of non-use.

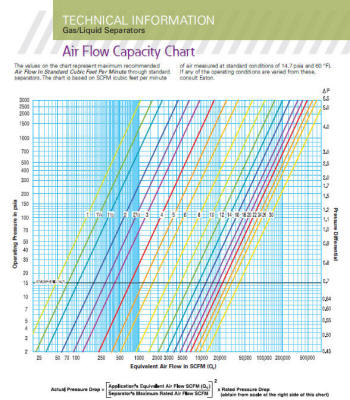

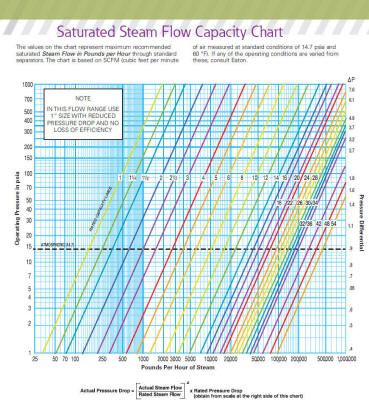

Refer to the maximum capacity chart below or use the dotted line within the graphs below to size an exhaust head. We can reduce the nozzle size of fabricated exhaust heads to match your pipeline size without the need for an adapter.

(Graphs are PDF file links to open full size in another browser window)

Reviews

There are no reviews yet.