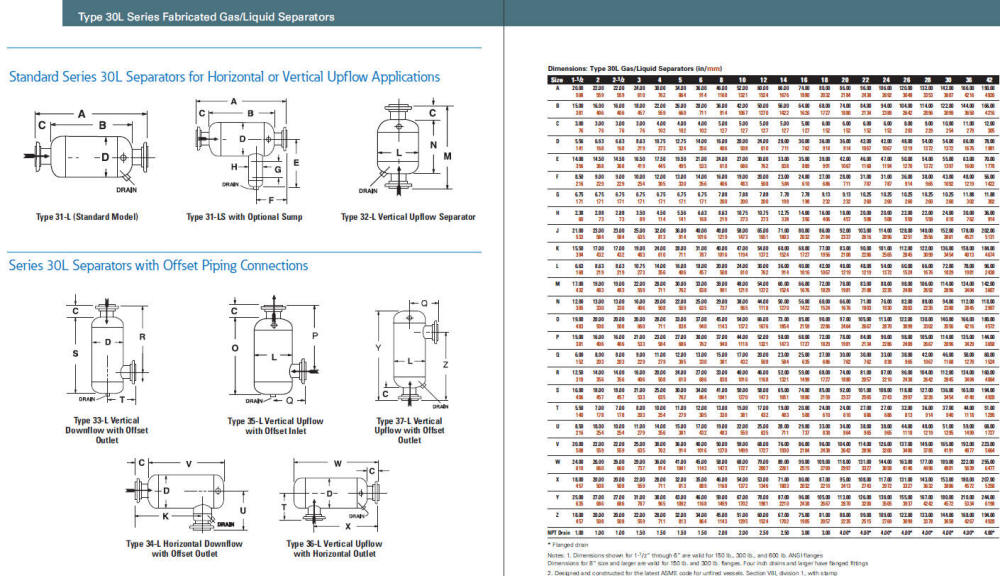

30L Style Horizontal Gas Liquid Separators

Gas liquid separators for light liquid loads

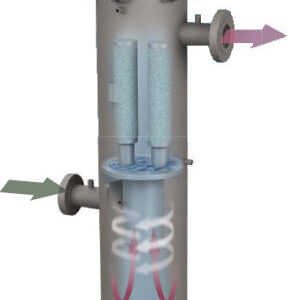

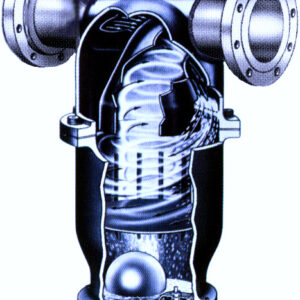

The Wright-Austin 30L series of in-line horizontal (or vertical down-flow) gas/liquid separators remove 99% of droplets and particles equal to or greater than 10 microns with a very compact design. As the moisture laden gas enters the separator, it encounters a curved, stationary blading structure welded to the inside of the vessel, and this causes a centrifugal force, propelling the droplets to the outer wall. The liquid coalesces and exits the separator’s drain.

As with all Wright-Austin gas/liquid separators, there are no moving parts, they are self-cleaning and require no maintenance. Wright Austin gas liquid separators employ a patented Vortex Containment Plate (VCP) and combined with centrifugal action assures maximum separation of entrainment with minimal chances of re-entrainment. Wright Austin accomplishes this without complex baffles, deflectors and other structures that obstruct the flow-stream, resulting in very low pressure drops.

What is the minimum velocity required through our separators?

There are no minimum velocities for our separators. Wright-Austin has run many tests over the years that support this contention.

There are several characteristics which cause separation. When the units are used at or near their maximum capacities the primary cause for separation is centrifugal force created, causing the liquid droplets to move to the outer walls. When the flow is reduced, the following methods become more important and are more responsible for the separation that takes place at the lower velocities.

Expansion/Gravity

The air, gas or steam expands in the vessel after leaving the inlet nozzle. This slows down the velocity at which the media and liquid molecules are moving. The liquid droplets tend to bump into each other and form larger droplets. The larger droplets are more likely to fall out due to gravity especially since the speed at which they are moving has also been reduced.

Agglomeration on surface

Droplets that form on the interior surfaces attract (agglomerate) more droplets. Big droplets fall to the bottom and drain out.

Change in Direction

The air, gas or steam flow changes directions (although slowly) inside the vessel in order to exit through the outlet nozzle. A change in flow direction always shears off some liquid droplets that do not make the turn.

Please send us mail explaining your requirement at sales@vanguarduae.com OR websales@pipelineproductsonline.com or call us 00971 556099497 we will give you feedback within 48 hrs.

Reviews

There are no reviews yet.